The new patent for “Battery and Body Integrated Structure and Vehicle” was officially applied by Xiaomi Automotive Technology.

What’s new?

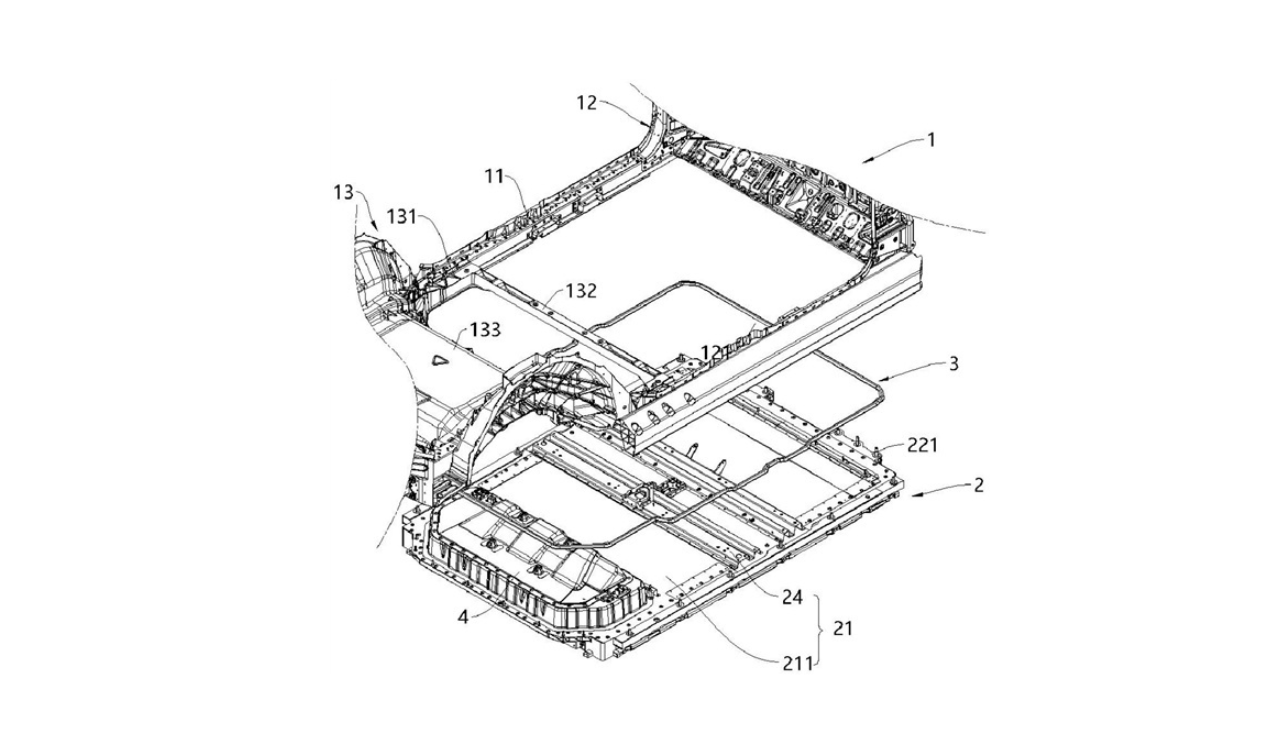

As per the doucment, the battery and body integrated structure includes a body and a power battery pack. The body includes two sill beams. The two sill beams are spaced apart along the left and right directions of the vehicle. Each sill beam is provided with a battery pack installation part.

Through the above technical solution, the top of the battery pack case is integrated with a cross beam. The cross beam can strengthen the main body of the case and improve the stiffness and side impact force transmission performance of the battery pack case.

The top of the main case serves as a floor panel, which is conducive to improving the performance of the battery pack case. The degree of integration of the vehicle can reduce the weight of the body structure, achieve lightweighting of the vehicle, and increase the vehicle’s cruising range.

With the upgrading and iteration of power battery technology and new energy vehicle manufacturing technology, car companies have gradually shifted from CTP (battery large module or module-less technology) to CTC in the choice of power battery installation. / CTB (battery chassis/body integration technology).

Process

As a new generation of battery system technology, CTC realizes the integrated design of batteries, chassis and lower body, etc., simplifies product design and production processes, improves vehicle stiffness and space, and increases battery capacity and driving range while reducing costs.

Compared with CTP moduleless technology, CTC mainly integrates the floor panel and the battery pack upper cover into one, reducing the gap between the two and the parts required for connection, simplifying the production steps, and the battery core is both for the whole It is the source of kinetic energy for the car and is also a structural member that increases the rigidity of the chassis/body.